Complete Overview of the Hidden Structure of a Cashew Nut Processing

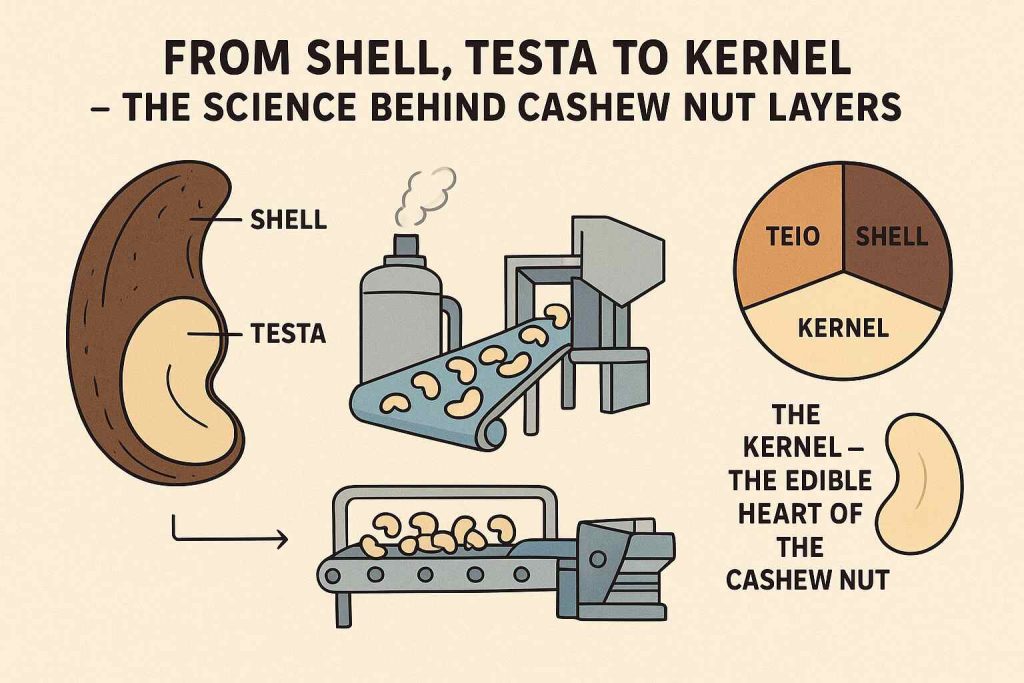

Cashew nuts are not only a tasty snack, but every nut is an invention of nature. A cashew nut has three primary layers: the outer shell, the inner skin, the testa, and the inner heart (edible). These layers may be crucial to know about efficient processing, safety, and quality output.

The modern Cashew Processing Machinery is built to process each of these layers with accuracy, minimizing waste, maintaining nutritional quality, as well as maximizing yield. Oscar Cashew Tech is the top Cashew Processing Machinery Manufacturer in India and provides both the Indian and international markets with turnkey solutions.

The Outer Shell – Nature’s Protective Armor

Cashew nut has an outer covering that is made of a hard and fibrous shell that covers the kernel, rendering it protective against physical damage, moisture, and pests. Its thickness and toughness depend on the type of cashew.

Structure and Function of the Cashew Shell

- Its shell serves to protect bacteria, insects, and moisture.

- It holds Cashew Nut Shell Liquid (CNSL), which is a toxic and oil-rich liquid that is useful in industries but should be handled with caution during processing.

Challenges in Shell Removal

The process of shell removal with the use of a manual method is dangerous due to CNSL, which is caustic and may burn the skin. Thus, the shell is softened by either steam cooking or mechanical shelling, which is intended to minimize kernel breakage.

Machinery Used for Shelling

- Shelling machines that are steam-based.

- Mechanical cutters and presses.

- Mechanical devices for accurate shelling.

With the help of modern machinery, it is possible to recover as many kernels as possible, in addition to keeping the workers safe against exposure to chemicals.

Cashew Nut Shell Liquid (CNSL): The Toxic Treasure

CNSL is an oily material in the shell of cashews, abundant in anacardic acid, cardanol, and cardol. CNSL has several industrial applications, although it is toxic to humans when raw.

Cashew Shell Oil Industrial Uses

- Applied in paints, brake linings, lubricants, and resins.

- Collected by product during shelling, which is a value addition to the cashew processing industry.

Protective Procedures in Shelling

- Employees are dressed in safety garments and gloves.

- Steam or hot-air shelling reduces exposure.

- The correct treatment of machinery will guarantee safe harvesting and industrial use of CNSL.

Testa Layer - The Thin Sheath enclosing the Kernel

The shell contains a thin reddish-brown skin beneath the shell, which envelops the kernel, called the testa. The testa is given little consideration, but it plays a very crucial protective role.

Role and Significance of the Testa

- Protects the kernel against microbial infection and oxidation.

- Affects the grade and appearance of the end product, cashew.

Peeling Process and Machinery

- The testa are dried and then peeled using mechanical peelers or air friction systems.

- Automation is used to guarantee less breakage of kernels and speed.

The Effects of Testa on Cashew Grading

- Kernels that have extra testa are graded down.

- The removal process is done efficiently to produce a high-quality and whole kernel product both in the domestic and export markets.

The Kernel - The Cashew Nut Edible Heart

The kernel is the part of the cashew nut that is nutritious and edible and is consumed all over the world due to its taste, texture, and nutritional value.

Nutritional Composition

- Protein-rich, healthy fats, vitamins, and minerals.

- Conforms to antioxidants that are healthy in the heart.

Processing and Grading

- Graped using both automated and manual graders and dried and graded by size, color, and shape.

- Grades as close to market value as possible, and international standards are achieved.

Packaging and Preservation

- Vacuum-packed or nitrogen-filled packaging inhibits oxidation and is used to maintain flavor.

- Low moisture content and hygiene packaging guarantee high shelf life.

The Separation of Each Layer by Cashew Processing Machinery

Modern cashew processing machinery is used to refine the complex process of transforming raw cashew nuts into market-ready kernels.

Mechanical Process Step-by-Step

- Shelling: The Hard shell is cut off by steam or mechanical cutting machines.

- Drying: Shell and kernels are dried to safe levels of moisture.

- Peeling: Machines that are either friction or air-based remove the testa.

- Grading: Sorting Vibratory sieves, optical sorters, and hand grading separate kernels based on their size and quality.

Automation guarantees high yield, safety, and consistency, which is a necessity both to the Indian and global cashew processing industries.

Scientific Composition of Cashew Nut Layers

Knowing about the physical and chemical properties of each layer is useful in maximizing processing.

Physical and Chemical Properties

| Layer | Key Properties | Industry / Food Importance |

| Shell | Fibrous has CNSL in it | industrial uses, and protects the kernel. |

| Testa | Thin reddish-brown skin | Antioxidant properties, influences grading. |

| Kernel | Fatty, nutritious | Domestic and export edible products. |

Each layer has different moisture, density, and oil content, which affect the design of the processing machinery.

Why Safe Shelling and Peeling Are Important

- Stops food contamination and preserves food safety.

- Guarantees protection against caustic exposure to CNSL for workers.

- Guarantees premium whole kernels in the international and domestic markets.

Modern Innovations in Cashew Processing Technology

Oscar Cashew Tech is the market leader with state-of-the-art equipment, which includes:

- Optical grading systems with the help of AI.

- Automated shell cutters and peelers.

- Drying and processing units that are energy efficient.

- Cashew processing plant turnkey solutions across the globe.

These inventions are more productive, safe, and sustainable, and Oscar Cashew Tech becomes a reliable Cashew Processing Machinery Manufacturer in India and the world.

The Secret Science of the Every Cashew

The cashew nut has a coating on the outside, through the shell, and to the kernel, which can be consumed. The shell of the nut has a vital role to play. Knowledge of these layers and excelling in Cashew Processing Machinery will guarantee high-quality kernels, safe processing, and maximum efficiency.

Oscar Cashew Tech is a combination of science, engineering, and innovation to offer machines that comply with international standards that enable businesses to produce high-quality cashews in India and other parts of the world.